After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

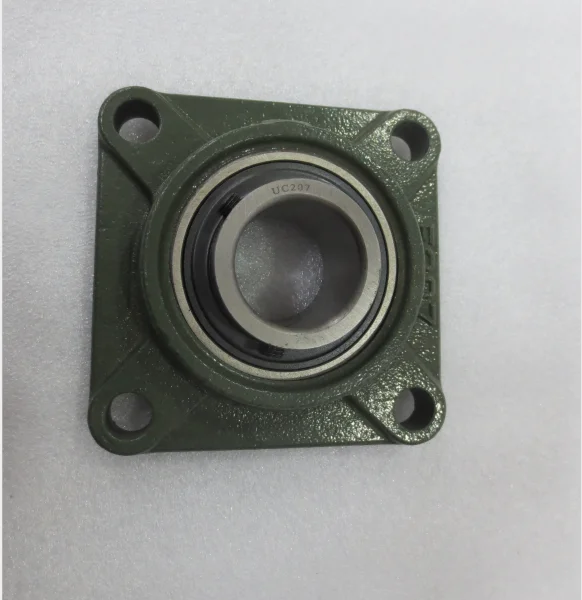

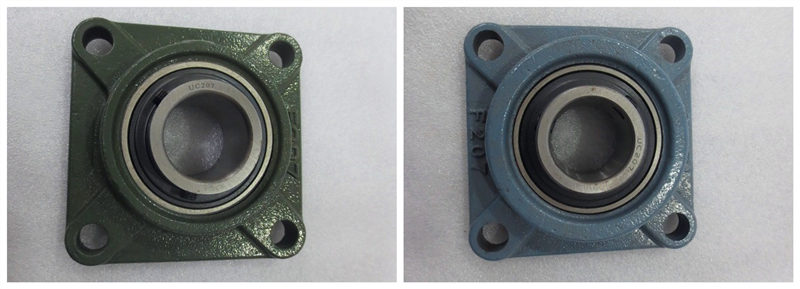

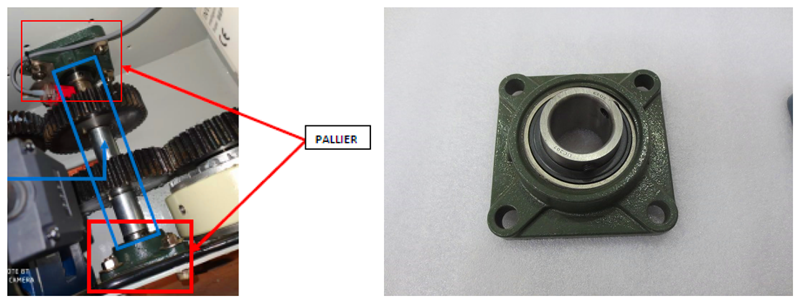

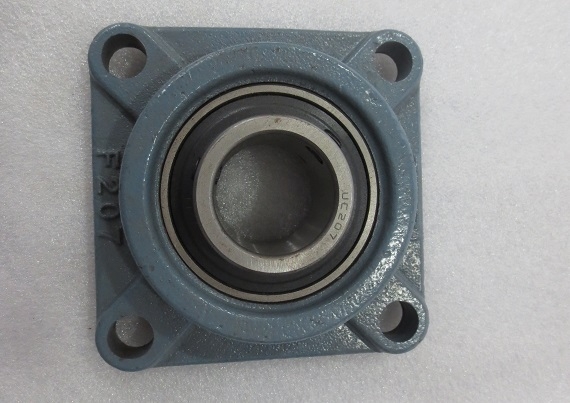

Unit Perumahan Galas Blok Bantal UCF 207

barang No.:

LTUCF207Pembayaran:

T/T, T/C, Paypal, Western Union...harga pasaran:

$5.5Harga:

$5.5/setasal produk:

Xiamenpelabuhan perkapalan:

Xiamen, ChinaMasa:

7 days after advanced payment

Butiran Pantas

| Jenis: | Blok bantal | bahan: | Keluli Chrome GCR15 |

| Tempat asal: | China | Bahan perumahan: | Besi tuang HT200 |

| OD: | 52 | ID: | 35 |

Keupayaan bekalan

500000 Keping/Keping setiap Bulan

Penerangan Produk

Permohonan: Mesin pemisah, tali tunda, peralatan pembajakan tanah, reaktor keluli tahan karat, mesin etsa, penyejuk beku suhu rendah, forklift, bahan binaan, mesin kimpalan plastik, mesin pemotong getah, mesin anyaman, kilang gelek, mesin gerudi jejari, mesin suapan, pengadun pneumatik, penghancuran peralatan, pam bebas bocor, versi merah mesin, dan lain-lain.

- Bunyi rendah

- Kelajuan tinggi

- Ketepatan tinggi

- Panjang umur

galas berkaitan

Sk galas papan makan

Galas Blok Bantals

Untuk dipasang dalam mesin gulung semula kami:

Pembungkusan produk

Sebelumnya:

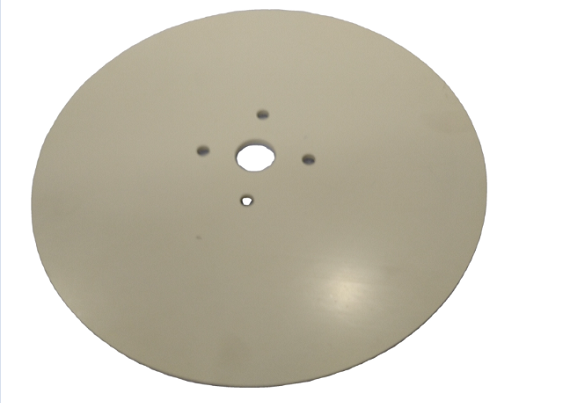

Plat PVC untuk mesin gulung semulaSeterusnya:

Istante ng rewinding machine

-

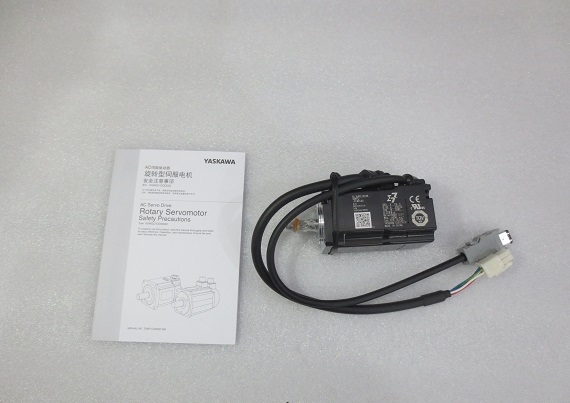

Motor servo berputar 100w

Motor servo berputar 100w

Butiran Produk Gambaran keseluruhan Butiran Pantas Jenis: Motor Servo Kecekapan: IE 2 Voltan AC: 115/120 V Kekerapan: 50/60 KHZ kuasa: 0.1kw Ciri Lindungi: Tertutup Sepenuhnya Keupayaan bekalan 100 Ekar/Ekar Sebulan Penerangan Produk Spesifikasi Sebagai salah satu aksesori majoy, motor servo digunakan untuk mengawal hampir semua bahagian yang bergerak pada mesin cetak skrin kami. Sudah tentu, motor adalah lebih daripada penggunaan ini, ia boleh dilihat di mana-mana dengan model yang berbeza, seperti kipas, mainan elektronik, semua jenis jentera dll. Model: 100W ; 750W; 1000W; Pembungkusan & Penghantaran

-

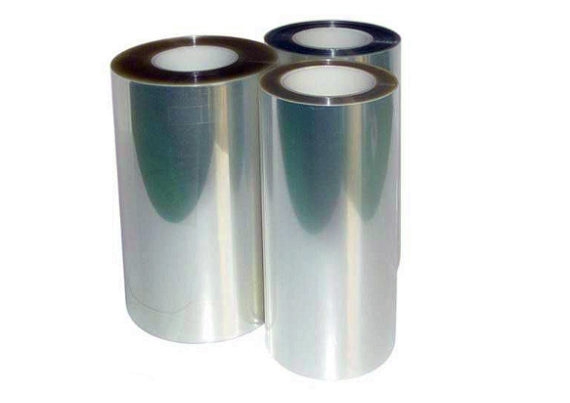

FILEM PETANG

FILEM PETANG

Butiran Produk Gambaran keseluruhan Butiran Pantas bahan: PET Jenis: Filem Regangan penggunaan: Filem pembungkusan, pembungkusan, percetakan, pelaminasi ciri: Pencetak Kertas, Pencetak Label, Pencetak Kad, Cetakan Tiub Kekerasan: Lembut Jenis Pemprosesan: Penyemperitan Berbilang Ketelusan: Telus Gred Automatik: Automatik Ketebalan: 0.05 Tempat asal: Fujian, China Saiz: Saiz Tersuai Diterima Nombor model: PET0.05 Jenama: LINGTIE kelebihan: ekonomi lebar: 30cm Warna: Transaprent Pembungkusan & Penghantaran Pembungkusan: pembungkusan yang sesuai untuk laut untuk jarak jauh Keupayaan Bekalan: 1000 Metrik Tan/Metrik Tan sebulan Masa Utama: Kuantiti (Set) 1 - 1>1 Anggaran Masa(hari)3 Untuk dirundingkan Penerangan Video watak: Ia adalah jenis bahan pembungkusan yang paling dilindungi alam sekitar. telah digunakan secara meluas untuk kawasan pembungkusan perubatan dan elektronik makanan. Dan untuk syarikat kami, ia digunakan secara meluas dalam label pemindahan haba. Kami juga menjual kepingan bahan-bahan PET kerana sesetengah pelanggan kami masih menggunakan mesin pencetak kepingan. Dan PET kami mempunyai 2 gaya untuk pilihan, filem kulit sejuk dan filem kulit panas. Untuk ketebalan, terdapat 3 saiz poplular, 75mikron, 50.5mikron dan 38mikron. Dan saiz helaian ialah 390 * 540mm. Dan mengikut keperluan anda, kami boleh membuat pesanan mengikut saiz. Pembungkusan produk

-

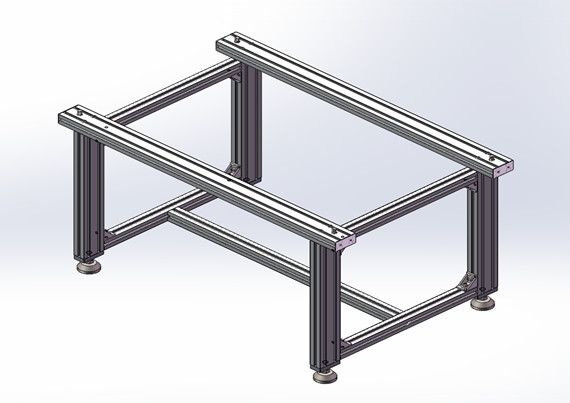

Istante ng rewinding machine

Istante ng rewinding machine

support frame para sa Rewinding machine, label counting machine . Makinarya ng siyentipiko at nakapangangatwiran disenyo , balanse at maaasahang operasyon , ang operasyon at pagpapanatili ng kaginhawahan .

-

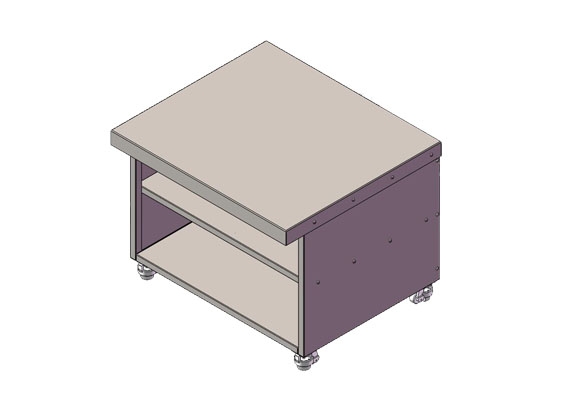

meja kerja untuk penggulung semula

meja kerja untuk penggulung semula

Jadual untuk mesin gulung semula Terdapat tiga saiz jadual ini untuk pilihan 1.L900*W800*H610mm 2.L900*W650*H610mm 3.L900*W650*H310mm

-

Roll rewewinding Machine

Roll rewewinding Machine

Mesin Rewinding Doktor yang disesuaikan ini digunakan untuk kasa perubatan semula di bawah ketegangan yang konsisten oleh perusahaan profesional Jepun.

hubungi kami : +86-18965820062

hubungi kami : +86-18965820062 E-mel : fany@lt-xm.com

E-mel : fany@lt-xm.com

Melayu

Melayu English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062