After-Sales Service Notice for Turkey Region

After-Sales Service Notice for Turkey Region Dear Valued Customers and Partners, We are pleased to inform you that our professional after-sales service team will be deployed in Turkey this week to provide technical support and maintenance services for screen printing machines and related accessories. For our long-term valued customers: Should your equipment require maintenance, troubleshooting, or technical consultation, please feel free to contact us at your earliest convenience. Our team is fully equipped to address your needs promptly and ensure the stable operation of your machinery. For friends with potential future requirements: We warmly welcome you to inquire about our product series, technical specifications, and after-sales support system. We also offer face-to-face consultation appointments—this is an excellent opportunity to discuss customized solutions tailored to your production needs and establish in-depth cooperation. To ensure efficient service arrangement, please reach out to us via the following channels to confirm your needs or schedule an appointment: - Email: fany@lt-xm.com - Phone: +8618965820062 - WeChat/WhatsApp: +8618965820062 We look forward to connecting with you in Turkey and providing you with high-quality, reliable technical support and service experience. Best regards, LINGTIE (XIAMEN)MACHINERY CO.,LTD 2026-1-21

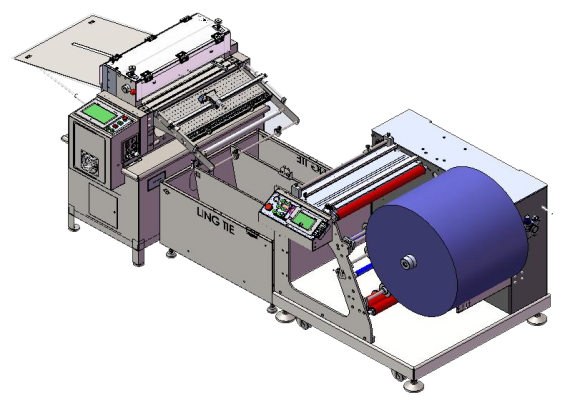

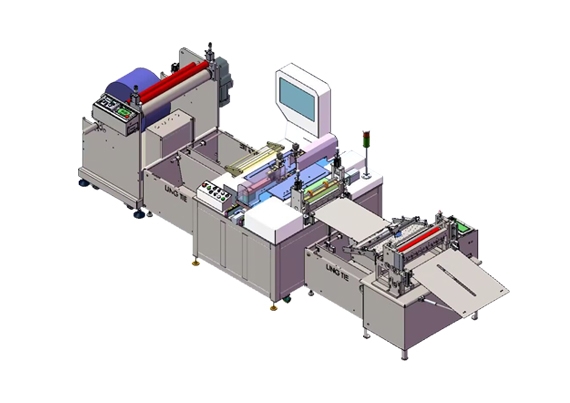

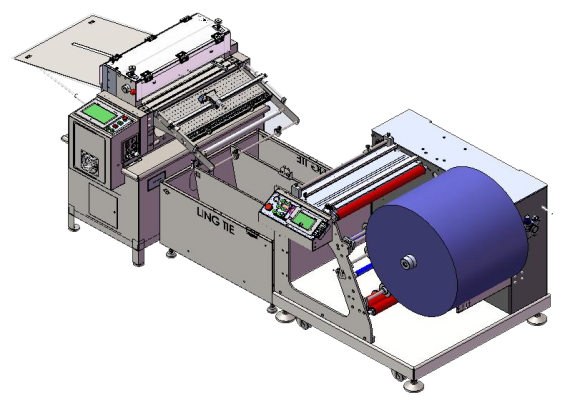

Roll automatik ke Mesin Keratan Lembaran

Jenama:

Lingtiebarang No.:

LTG-360harga pasaran:

$7800asal produk:

Chinapelabuhan perkapalan:

Xiamen,ChinaMasa:

7 days after received 30% payment

Nama Produk: Kertas Bercetak Roll to Sheet Cutting Machine

Roll kertas bercetak ini ke mesin pemotong lembaran tergolong dalam percetakan selepas akhbar peralatan, sepadan dengan peranti sampingan seperti mesin rewinding, mesin makan, penggunaan sheeter. Pelbagai bahan dalam roll boleh dipotong seperti kertas, PET, PVC, PC, BOPP, kerajang aluminium, dan lain-lain

Parameter Mesin Pemotongan Lembaran automatik ke Mesin

Maks. lebar bahan: 360mm

Toleransi adalah 0.05 mm, Ketepatan: 0.1mm

Kelajuan pemotongan adalah 110 m / min

Memotong ketepatan 0.01 mm

Maks. lebar pemotongan adalah 600 mm

Panjang max.cutting adalah 0.1 ~ 9999.9 mm

Ketebalan bahan adalah 0.5 mm-15 mm

Toleransi: 0.05 mm, Ketepatan: 0.01 mm

Ciri-ciri Roll Roll to Sheet Cutting Machine

1. roll roll ke mesin pemotong lembaran ini menggunakan antara muka manusia-mesin dan sistem PLC untuk mengawal

2. Roll Cut Sheet Cutting Machine mengamalkan sunx Panasonic memastikan pemotongan tepat 0.01 mm

3. Paper Reel to Sheet Cutting Machine dilengkapi dengan peranti vakum mengelakkan awal

4. Peralatan Pemotong Sheeter ini boleh mempratetkan memotong panjang, kelajuan, kuantiti, dan ia akan menghafal mereka apabila menjalankan masa berikutnya

Di mana untuk membeli Rolling Sheet Cutting Machine?

Dengan lebih daripada 10 tahun pengalaman, Lingtie (Xiamen) Machinery Co., Ltd. telah menjadi pembekal yang terkenal untuk roll roll mesin percetakan skrin, peralatan pasca akhbar, dan peralatan sampingan . Kami adalah pengeluar peralatan asal, yang melayani pelanggan di seluruh dunia seperti Amerika Utara, Amerika Selatan, Timur Tengah, pelanggan Asia Tenggara, menerima kadar kepuasan pelanggan yang tinggi. Selagi anda seorang pembeli percetakan profesional, kami adalah pengeluar percetakan profesional.

Sebelumnya:

Roll to Sheet Cutting Machine

-

Roll to Sheet Cutting Machine

Roll to Sheet Cutting Machine

Rotary Roll to Sheet Cutting Machine yang digunakan secara meluas dalam Pakaian, Minuman, Kimia, Komoditi, Jentera, Perkakasan, Perubatan.

-

Gulung ke Mesin Pemotong Lembaran LTG-600

Gulung ke Mesin Pemotong Lembaran LTG-600

Mesin Pemotong Gulung ke Lembaran , pemotong untuk memotong label atau bahan gulung sehingga lebar 600 mm.

-

gulung ke mesin pemotong penebuk lembaran

gulung ke mesin pemotong penebuk lembaran

Ciri mesin penggulungan dan penebuk foil automatik: Operasi mudah: Tetapkan mod kerja terus pada monitor komputer. Ketepatan tinggi: Kamera dalam julat pengecaman secara automatik mengesan imej, dan komputer menganalisis serta mengawal pergerakan. Kelajuan pantas: Kamera mempunyai masa tindak balas yang singkat, dan setelah imej ditemui, ia boleh menebuk lubang pada kedudukan imej. Kefungsian berkuasa: Imej sampel boleh disimpan dan diakses terus melalui sistem komputer, membenarkan peningkatan perisian masa nyata. Jaminan kualiti: Komponen utama seperti injap pengatur tekanan, silinder, injap solenoid dan panduan linear diimport, memastikan jangka hayatnya. Kadar pengecaman tinggi: Sumber cahaya khas secara automatik boleh mengenal pasti corak lubang kedudukan pada bahan yang sangat reflektif dan sangat legap, dan boleh mengimbangi imej yang tidak lengkap. Sistem mesin tebukan automatik dwi-kepala menangkap grafik sampel dalam julat kamera yang boleh dilihat melalui komputer. Analisis melibatkan kawalan anjakan komponen penghantaran dan tebukan dengan komponen pneumatik. Ia memenuhi keperluan pelanggan untuk kelajuan tebukan yang tinggi, ketepatan tinggi dan kemudahan pengendalian. â Mesin penebuk biasanya dirujuk sebagai peranti pemprosesan lubang sasaran. Lubang sasaran pertama kali digunakan dalam proses pelapis papan litar berbilang lapisan PCB. Dalam tahun-tahun kebelakangan ini, mesin penebuk kedudukan yang digunakan untuk pemprosesan kedudukan biasanya dipanggil "mesin menembak sasaran". Memandangkan ketepatan pemesinan lubang sasaran secara langsung mempengaruhi ketepatan produk, mesin penebuk, dilengkapi dengan pengimbasan kedudukan penglihatan CCD dan sistem penentududukan automatik dikawal komputer, boleh mencapai ketepatan dan kestabilan pemesinan lubang penentududukan dalam julat 0.015 milimeter. Oleh itu, semakin banyak syarikat telah memperkenalkan mesin tebukan sebagai peralatan khusus untuk pemprosesan kedudukan bagi menggantikan penggerudian manual tradisional. Ini sangat meningkatkan kualiti produk, mengurangkan sekerap, menjimatkan kos dan meningkatkan pengeluaran. Ia meningkatkan daya saing pasaran perusahaan dan merupakan senjata rahsia yang banyak syarikat diamkan. â¡ Mesin penebuk boleh dikelaskan berdasarkan tahap automasi ke dalam mesin penebuk manual, mesin penebuk kedudukan/penjajaran automatik dan mesin penebuk automatik sepenuhnya. Ia juga boleh dikategorikan berdasarkan objek pemprosesan, seperti mesin penebuk papan fleksibel, mesin penebuk suis membran, mesin penebuk filem, mesin penebuk papan nama, dan mesin penebuk filem kalis letupan telefon bimbit. Sebagai pengeluar mesin tebukan profesional, syarikat kami terutamanya menghasilkan mesin tebukan untuk papan litar fleksibel, papan litar, PCB, papan litar filem nipis, serta papan tanda, papan nama dan penebuk filem telefon mudah alih dengan lubang kedudukan. Mesin penebuk automatik mempunyai keperluan khusus untuk pengecaman grafik dalam penebuk kedudukan ketepatan tinggi. Mereka memerlukan garis grafik bulat yang jelas dan seragam untuk kedudukan. Dalam kes grafik yang tidak lengkap, kelegapan tinggi atau pencetakan yang tidak jelas, penebuk automatik boleh dicapai melalui pengecaman dan pembaikan perisian atau pemilihan sumber yang sesuai.

-

Gulung ke Mesin Pemotong Lembaran LTG-600

Gulung ke Mesin Pemotong Lembaran LTG-600

Mesin Pemotong Gulung ke Lembaran , pemotong untuk memotong label atau bahan gulung sehingga lebar 600 mm.

-

Reel-to-Reel Counters Label counter Rewinder with Anti-static function

Reel-to-Reel Counters Label counter Rewinder with Anti-static function

Reel-to-Reel Counters Label counter Rewinder with Anti-static function Reel to reel off line counting station provide a quick and easy way to count the number of labels on a roll.

hubungi kami : +86-18965820062

hubungi kami : +86-18965820062 E-mel : fany@lt-xm.com

E-mel : fany@lt-xm.com

Melayu

Melayu English

English français

français Deutsch

Deutsch русский

русский italiano

italiano español

español português

português Nederlands

Nederlands العربية

العربية 한국의

한국의 Türkçe

Türkçe Polski

Polski magyar

magyar ไทย

ไทย Việt

Việt हिंदी

हिंदी Indonesia

Indonesia Limba română

Limba română 中文

中文

+86-18965820062

+86-18965820062

+8618965820062

+8618965820062